Hot Line

400-800-6106

Hot Line

400-800-6106

NTEK failure analysis service mainly includes performance testing for product development, trial production, production and incoming quality assurance, including component analysis, mechanical performance, thermal performance, electrical performance, chemical performance and reliability evaluation; for electronic products in the development stage Provide analysis services for failures in the reliability test phase and client use phase; provide product analysis and evaluation services for the structural reliability, process reliability, performance reliability and long-term reliability of electronic products. Provide reliability quality assurance testing and analysis services for supply chain products.

Its testing scope includes professional services such as metal materials, polymer materials, electronic products, PCB boards, and coating materials.

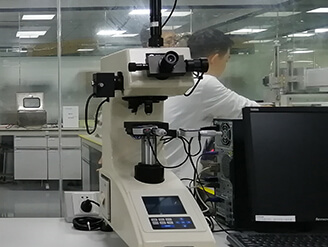

The test items include precision fixed-point section analysis, FIB ultra-precision section preparation, microscopic observation, thermal performance testing, and SEM scanning electron microscope observation on the machine.

Hitachi transmission electron microscope, thermogravimetric analyzer, 3D optical digital display mirror, metallographic microscope, infrared spectrometer, X-Ray detector and many other large-scale modern analysis and testing instruments.

A complete set of failure analysis solutions: scenario analysis + step analysis + data analysis.

Analysis of root causes of product defects and improvement of product quality.

Improve enterprise production quality control and data analysis technology to prevent recurrence of failures.

Analyze product defects in design, manufacturing, process or use, and improve methods to solve problems.

To dig out the failure mechanism and arbitrate failure accidents.

Submit failure analysis report and propose preventive measures.

Number of service items

Total number of performances completed

Total customer praise

Total number of customer groups

NTEK laboratory is established and implemented in strict accordance with the ISO / IEC17025: 2005 standard. The laboratory has passed the audit of the International Electrotechnical Commission's Electrotechnical Product Qualification Testing and Certification Organization (IECEE) and has become a CBTL under UL. The company has obtained the qualification certificate of the import and export commodity inspection and appraisal agency issued by the General Administration of Quality Supervision, Inspection and Quarantine. It is a designated laboratory of the National Compulsory Product Certification (CCC), a testing laboratory contracted by the China Quality Certification Center (CQC), and a CMA test Laboratory, fully qualified to issue third-party testing reports.