Basic introduction

Hose (hose) assembly is an auxiliary device commonly used in hydraulic systems. It is made of high-pressure steel wire braided or wound rubber hose and steel joints with special equipment. It is used to connect various types of hydraulic components in hydraulic systems. It is mainly used for hydraulic power at working temperature of -40 ℃ to + 100 ℃ Transfer or transport high-pressure media such as water, gas, and oil to ensure the circulation of liquid and transfer of liquid energy.

Hose is widely used in automotive, aerospace, petroleum, chemical, marine, engineering machinery and other fields. In automobiles, it is mainly used in major assemblies such as brakes, transmissions, engines, air conditioning systems, and cooling systems; it is related to the brake safety and performance of automobiles. Considering the importance of the hose assembly in the system, there are many standards and specifications for hose testing at home and abroad. The development and improvement of each new model will complete various hose tests in accordance with the corresponding test specifications of the OEM.

Test capability

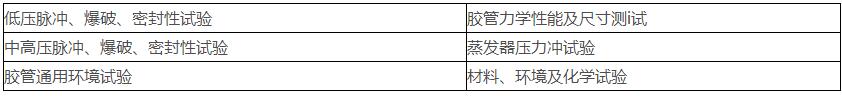

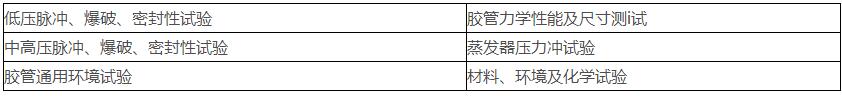

Test ability of automobile tube and evaporator:

Performance index of tube

Our advantage

Hot Line

400-800-6106

Hot Line

400-800-6106